Izinhlelo zokusebenza

Izinto eziyisisekelo kumapuleti ayinhlanganisela yedayimane zithola ukusetshenziswa emikhakheni eyahlukene ngokusekelwe ezimpahleni zazo, kuhlanganisa kodwa kungagcini lapho:

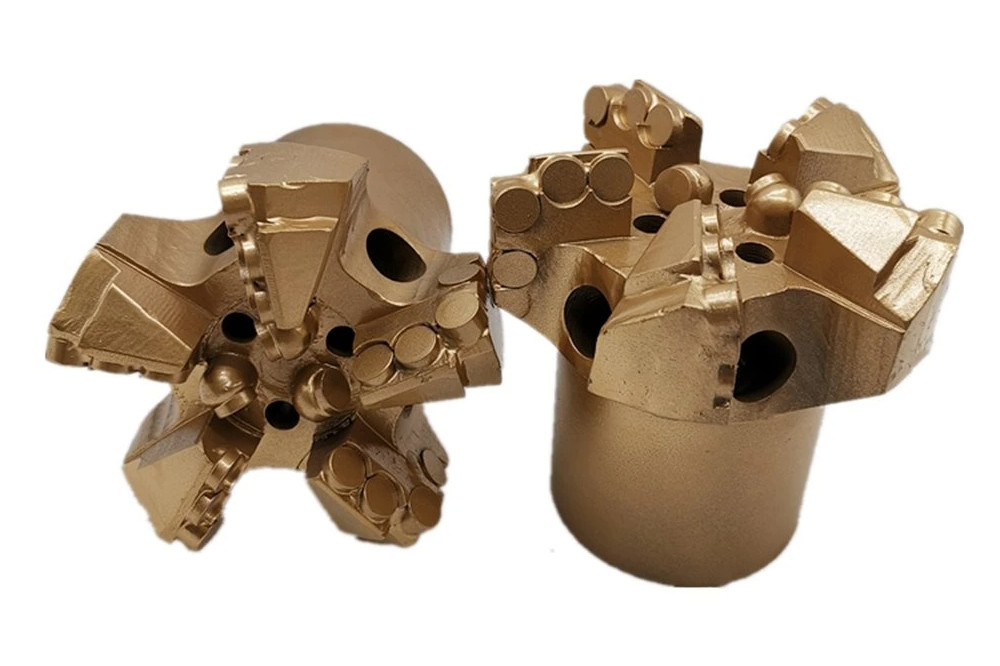

Amathuluzi Okusika Nokugaya:

Izinto eziyisisekelo kumapuleti ayinhlanganisela yedayimane zivame ukusetshenziselwa ukwenza amathuluzi okusika nokugaya njengamasondo okugaya nama-blades.Izici zezinto eziyisisekelo zingathonya ukuqina kwethuluzi, ukuqina, nokuvumelana nezimo.

Izinto Zokuqeda Ukushisa:

I-thermal conductivity ye-base material ibalulekile kumadivayisi akhipha ukushisa.Amapuleti ayinhlanganisela yedayimane angasebenza njengezisetshenziswa ze-substrate zamasinki okushisa asebenza kahle kakhulu ukuze aqhube kahle ukushisa.

I-Electronic Packaging:

Izinto eziyisisekelo kumapuleti ayinhlanganisela yedayimane zisetshenziswa ekufakweni kwezingxenye ze-elekthronikhi ezinamandla amakhulu ukuze kuthuthukiswe ukusebenza kahle kokukhipha ukushisa nokuvikela izinto zikagesi.

Ukuhlolwa Kokucindezela Okuphezulu:

Ekuhlolweni kwengcindezi ephezulu, okuyisisekelo kungaba yingxenye yamaseli anomfutho ophezulu, alingisa izakhiwo zezinto ezibonakalayo ngaphansi kwezimo zokucindezela okukhulu kakhulu.

Izici

Izici zezinto eziyisisekelo kumapuleti ayinhlanganisela yedayimane zithinta ngokuqondile ukusebenza nokusetshenziswa kwento.Nazi ezinye izici ezingaba khona zezinto eziyisisekelo:

I-Thermal Conductivity:

I-thermal conductivity ye-base material ithinta umthamo we-thermal conduction wepuleti yonke eyinhlanganisela.Ukushisa okuphezulu kwe-thermal kusiza ukudlulisa ukushisa ngokushesha endaweni ezungezile.

Amandla Emishini:

Izinto eziyisisekelo zidinga ukuba namandla anele okusebenza ukuze kuqinisekiswe ukuzinza nokuqina kwayo yonke ipuleti eliyinhlanganisela phakathi nokusika, ukugaya, nezinye izinhlelo zokusebenza.

I-Wear Resistance:

Izinto eziyisisekelo kufanele zibe nokumelana okuthile kokugqoka ukuze zimelane nezimo eziphakeme zokungqubuzana nokucindezeleka ngesikhathi sokusika, ukugaya, nokusebenza okufanayo.

Ukuzinza Kwekhemikhali:

Izinto eziyisisekelo zidinga ukuhlala zizinzile ezindaweni ezihlukahlukene futhi zimelane nokugqwala kwamakhemikhali ukuze kuqinisekiswe ukusebenza kwesikhathi eside.

Amandla Okubambisana:

Izinto eziyisisekelo zidinga amandla amahle okubopha namakristalu edayimane ukuze kuqinisekiswe ukuzinza nokuthembeka kwayo yonke ipuleti eliyinhlanganisela.

Ukuzivumelanisa nezimo:

Ukusebenza kwezinto eziyisisekelo kufanele kufane nezakhiwo zamakristalu edayimane ukuze kuzuzwe ukusebenza okuphezulu ezinhlelweni ezithile.

Sicela uqaphele ukuthi kunezinhlobonhlobo zezinto eziyisisekelo kumapuleti ayinhlanganisela yedayimane, ngalinye linezakhiwo ezihlukile kanye nezicelo.Ngakho-ke, ekusetshenzisweni okukhethekile, izinto eziyisisekelo ezifanele kufanele zikhethwe ngokusekelwe ezidingweni

Ulwazi Lwempahla

| Amabanga | Ukuminyana(g/cm³)±0.1 | Ukuqina(HRA)±1.0 | I-Cabalt(KA/m)±0.5 | I-TRS (MPa) | Isicelo Esinconyiwe |

| KD603 | 13.95 | 85.5 | 4.5-6.0 | 2700 | Ifanele izinto eziyisisekelo zepuleti eliyinhlanganisela yedayimane ezisetshenziswa ku-geology, ama-coalfields, nezinye izinhlelo zokusebenza ezifanayo. |

| KD451 | 14.2 | 88.5 | 10.0-11.5 | 3000 | Ifanele izinto eziyisisekelo zepuleti eliyinhlanganisela yedayimane ezisetshenziswa ekukhishweni kwendawo yamafutha. |

| K452 | 14.2 | 87.5 | 6.8-8.8 | 3000 | Ifanele izinto eziyisisekelo ze-PDC blade |

| KD352 | 14.42 | 87.8 | 7.0-9.0 | 3000 | Ifanele izinto eziyisisekelo ze-PDC blade. |

Ukucaciswa Komkhiqizo

| Uhlobo | Ubukhulu | |||

| Ububanzi (mm) | Ubude (mm) | |||

| I-KY12650 | 12.6 | 5.0 | |

| I-KY13842 | 13.8 | 4.2 | ||

| I-KY14136 | 14.1 | 3.6 | ||

| I-KY14439 | 14.4 | 3.9 | ||

| YT145273 | 14.52 | 7.3 | |

| I-YT17812 | 17.8 | 12.0 | ||

| I-YT21519 | 21.5 | 19 | ||

| I-YT26014 | 26.0 | 14 | ||

| I-PT27250 | 27.2 | 5.0 | |

| I-PT35041 | 35.0 | 4.1 | ||

| I-PT50545 | 50.5 | 4.5 | ||

| Iyakwazi ukwenza ngokwezifiso ngokuya ngosayizi kanye nemfuneko yomumo | ||||

Mayelana NATHI

I-Kimberly Carbide isebenzisa imishini yezimboni ethuthukisiwe, uhlelo lokuphatha oluyinkimbinkimbi, kanye namakhono amasha ayingqayizivele ukuze anikeze amakhasimende omhlaba wonke emkhakheni wamalahle ngobuchule obuqinile bezobuchwepheshe kanye nenqubo ebanzi ye-Three-Dimensional VIK.Imikhiqizo inokwethenjelwa ngekhwalithi futhi ibonisa ukusebenza okuphezulu, okuhambisana namandla amakhulu obuchwepheshe angenawo ontanga.Inkampani iyakwazi ukuthuthukisa imikhiqizo esekelwe ezidingweni zamakhasimende, kanye nokwenza ngcono okuqhubekayo kanye nesiqondiso sobuchwepheshe.